Greenhouse gas emissions, primarily driven by fossil fuel combustion, have surged dramatically over recent decades. In 2022 alone, energy-related processes released 41.3 gigatons of CO2 equivalents, with carbon dioxide contributing nearly 89% of the total emissions.

Amidst this alarming trend, the United Nations Climate Change Conference (COP28) heralded the “beginning of the end” for fossil fuels, emphasizing the urgency of alternative solutions.

The transition to renewable energy has gained momentum, with renewable electricity generation reaching 7,858 terawatt-hours in 2021. Despite this progress, certain industries—notably heavy transport and industrial processes—pose significant challenges due to their reliance on high-density chemical energy carriers.

Technologies like Power to X (PtX) and Carbon Capture and Utilization (CCU) have emerged as critical tools in addressing these challenges, offering pathways to decarbonize these sectors and meet net-zero targets by 2050.

Carbon capture technologies, particularly chemical scrubbing, are leading the way in reducing emissions. This mature technology uses solvent-based processes to absorb CO2 from industrial flue gases. However, traditional methods come with high energy costs, consuming up to 30% of a typical power plant’s output.

Current systems require thermal energy of 3.5 to 4 gigajoules per ton of CO2 for desorption—a significant expense that researchers are striving to reduce.

Innovations such as optimized desorption processes and advanced solvent blends have shown promise, lowering energy demands to 1.9–3.6 gigajoules per ton of CO2 in pilot studies. These advancements improve the efficiency of carbon capture, paving the way for broader adoption in industries resistant to electrification. Yet, the costs of storage, transport, and purification of captured CO2 remain obstacles to its widespread use.

Related Stories

Emerging integrated carbon capture and utilization (ICCU) technologies aim to address these challenges by converting captured CO2 directly into valuable compounds. This eliminates the need for costly intermediate steps such as dehydration and compression.

Techniques such as thermocatalysis, electrochemical catalysis, and biofixation with microalgae offer diverse approaches to transform carbon emissions into useful resources. However, these methods require further refinement to overcome issues like energy demands, catalyst durability, and gas conditioning.

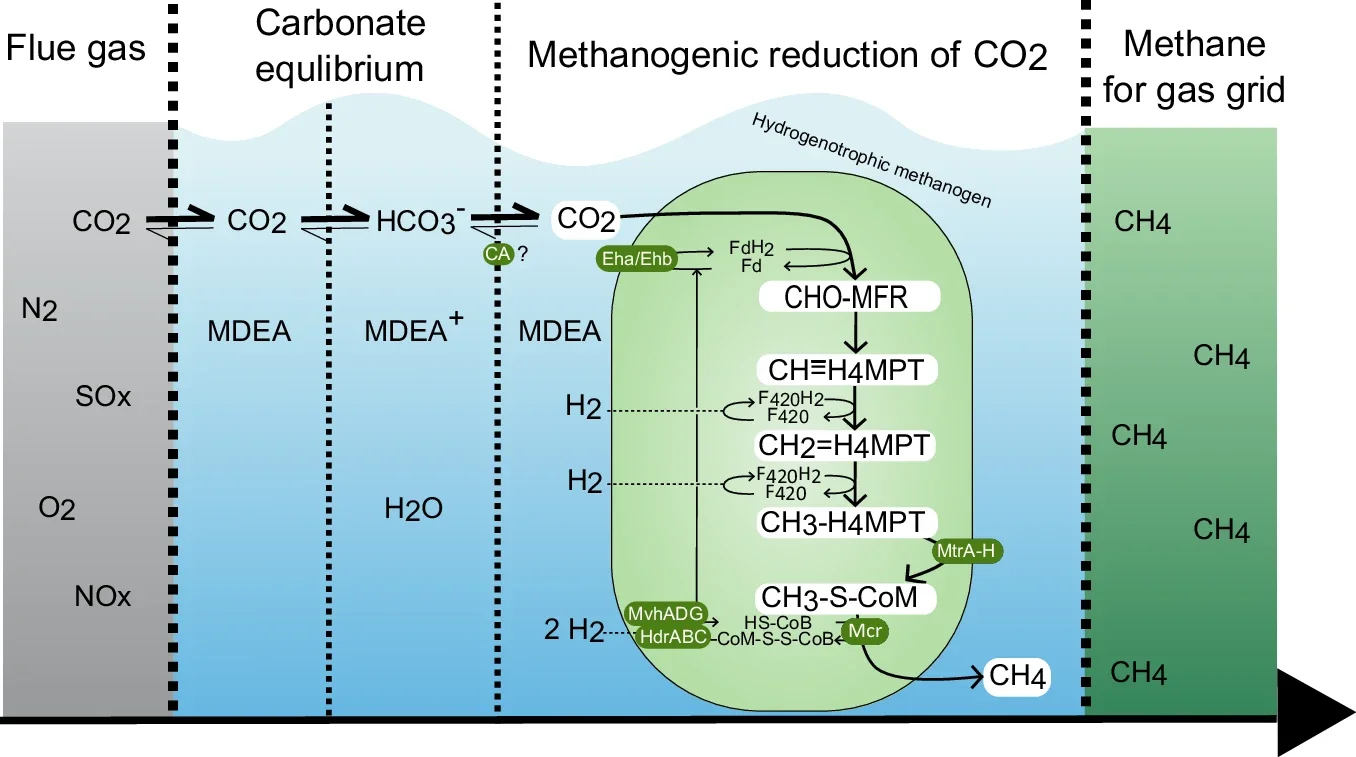

In a groundbreaking development, researchers at Aarhus University have introduced a bio-integrated carbon capture and utilization (BICCU) technology that leverages microorganisms to simplify the carbon conversion process. Unlike conventional methods, which rely on high heat to release and refine CO2, this approach uses microbial bioreactors to absorb and transform CO2 directly within the capture unit.

“Microorganisms are hyper-specialized in the process of absorbing and converting CO2, a capability they have refined over billions of years,” explains Dr. Mads Ujarak Sieborg, a postdoctoral researcher and a lead author of the study.

These microbes metabolize CO2, converting it into products such as methane or chemical precursors like acetic acid. These outputs can replace fossil-based resources in industrial applications, offering a renewable and sustainable alternative.

Methanogenic microorganisms, key players in this system, thrive in anaerobic environments and convert CO2 into methane using renewable hydrogen from water electrolysis.

These microbes, including species such as Methanobacterium and Methanoculleus, excel in tolerating contaminants like hydrogen sulfide and sulfur dioxide, which would otherwise deactivate chemical catalysts. This resilience makes them ideal for handling flue gases, where CO2 is mixed with other gases.

Despite its promise, the BICCU system faces technical hurdles. The microorganisms require hydrogen to fuel their metabolic processes, which depends on scalable and cost-effective electrolysis. Additionally, flue gases often contain oxygen, a compound detrimental to the anaerobic methanogens. Addressing these issues is crucial for large-scale adoption.

“Hydrogen is the limiting factor in the system today,” notes Amalie Kirstine Hessellund Nielsen, a Ph.D. student and co-author of the study. “We need efficient reactors and systems to integrate these processes effectively. But with existing advancements in reactor technology, these challenges are not insurmountable.”

Biological carbon capture provides a compelling incentive for industries to embrace emission-reducing technologies. Traditional carbon capture is energy-intensive, consuming nearly one-third of a power plant’s output.

In contrast, the biological process operates at much lower temperatures, significantly cutting costs. Moreover, the simultaneous production of useful byproducts like green natural gas enhances its economic appeal.

Currently, biogas plants have begun capturing CO2 from their production streams, which contain up to 50% CO2. Expanding this capability to industrial flue gases, where CO2 concentrations range from 5% to 10%, could greatly increase the availability of carbon feedstock for reuse. This would complement renewable energy strategies, filling a critical gap in decarbonizing industries that rely on high-density energy carriers.

As industries strive for net-zero emissions, the role of carbon capture and utilization technologies becomes indispensable. Systems like BICCU exemplify how innovative approaches can transform a liability—carbon emissions—into a valuable resource. While challenges remain, advancements in bioreactor efficiency and hydrogen production promise to accelerate adoption.

“In a net-zero future, we need technologies that recycle CO2 instead of extracting more from the ground,” emphasizes Nielsen. Such solutions not only reduce greenhouse gases but also provide sustainable alternatives to fossil-based resources.

Achieving carbon neutrality demands a multifaceted approach, combining renewable energy, advanced carbon capture, and sustainable utilization. Technologies like BICCU hold the potential to revolutionize industries, making the vision of a circular carbon economy an achievable reality.

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get The Brighter Side of News’ newsletter.

The post New technology converts CO2 in chimney smoke into new products appeared first on The Brighter Side of News.