Plastic has become part of everyday life, but its benefits come with a serious cost. Cheap, durable plastics accumulate in landfills and spread through soil, rivers, and oceans. Over time, they fragment into microplastics, particles smaller than 5 millimeters that now appear in nearly every ecosystem. Studies have also detected them in human tissues and blood, where researchers have linked exposure to risks such as cerebral thrombosis.

Efforts to solve this problem have often fallen short. Many products sold as “biodegradable” degrade slowly in real environments and still shed microplastics. Burning plastic waste removes debris but releases greenhouse gases that worsen climate change. Against this backdrop, researchers in Japan report a different approach, one designed to make plastics that fully disappear rather than linger.

Scientists led by Takuzo Aida at the RIKEN Center for Emergent Matter Science have developed a plant-based plastic that matches the strength of conventional materials yet dissolves cleanly in seawater. The findings appear in the Journal of the American Chemical Society and build on the team’s earlier work on plastics that break apart through reversible molecular bonds.

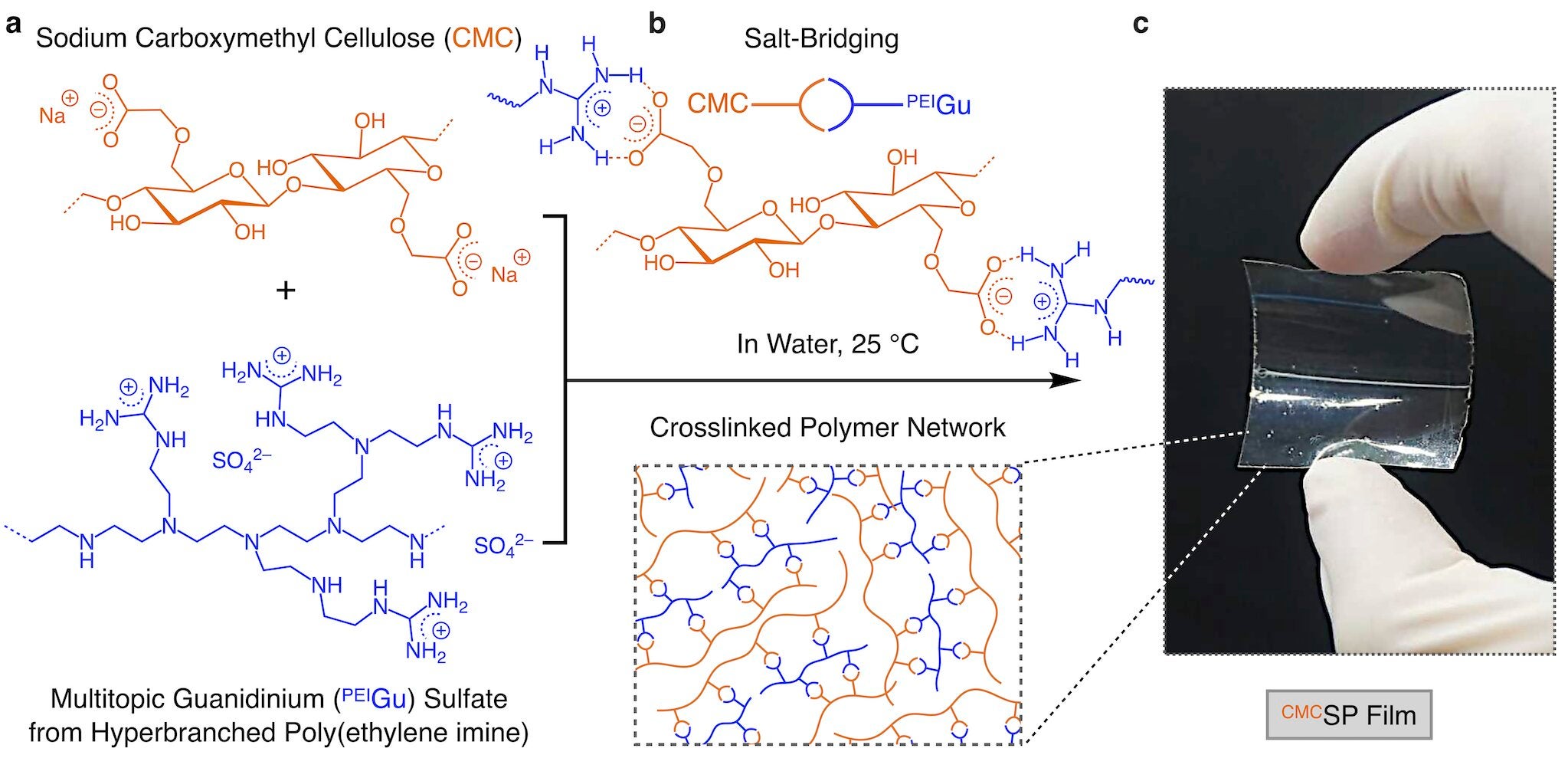

Rather than relying on hard carbon–carbon backbones that resist decay, the researchers designed plastics held together by strong but reversible attractions. These so-called supramolecular plastics behave like everyday plastics during use. At the end of their life, however, their internal bonds come apart, allowing the material to dissociate into small, metabolizable components instead of persistent fragments.

The new work centers on cellulose, the most abundant organic compound on Earth. Nature produces roughly one trillion tons of it each year. Using raw cellulose is difficult because it barely dissolves and some modified forms persist in the environment. To solve this, the team chose carboxymethyl cellulose, or CMC, a water-soluble, FDA-approved cellulose derivative already used in food and medicine.

CMC carries multiple negative charges, making it ideal for forming reversible “salt bridges” with positively charged partners. After extensive testing, the researchers paired it with a safe, positively charged polymer called polyethylene-imine guanidinium, or PEIGu. Toxicity tests confirmed that both the starting materials and the final plastic were not genotoxic.

When solutions of CMC and PEIGu were mixed in water, their opposite charges pulled them together. This triggered liquid–liquid phase separation, producing dense polymer-rich droplets that locked into a solid network once dried. The result was a clear, glassy plastic the team named CMCSP.

The properties of CMCSP rival many petroleum-based plastics. It is stiff and strong, with mechanical strength comparable to common engineering polymers, and it transmits about 90 percent of visible light. X-ray studies showed it lacks crystalline order, giving it an even, glass-like appearance.

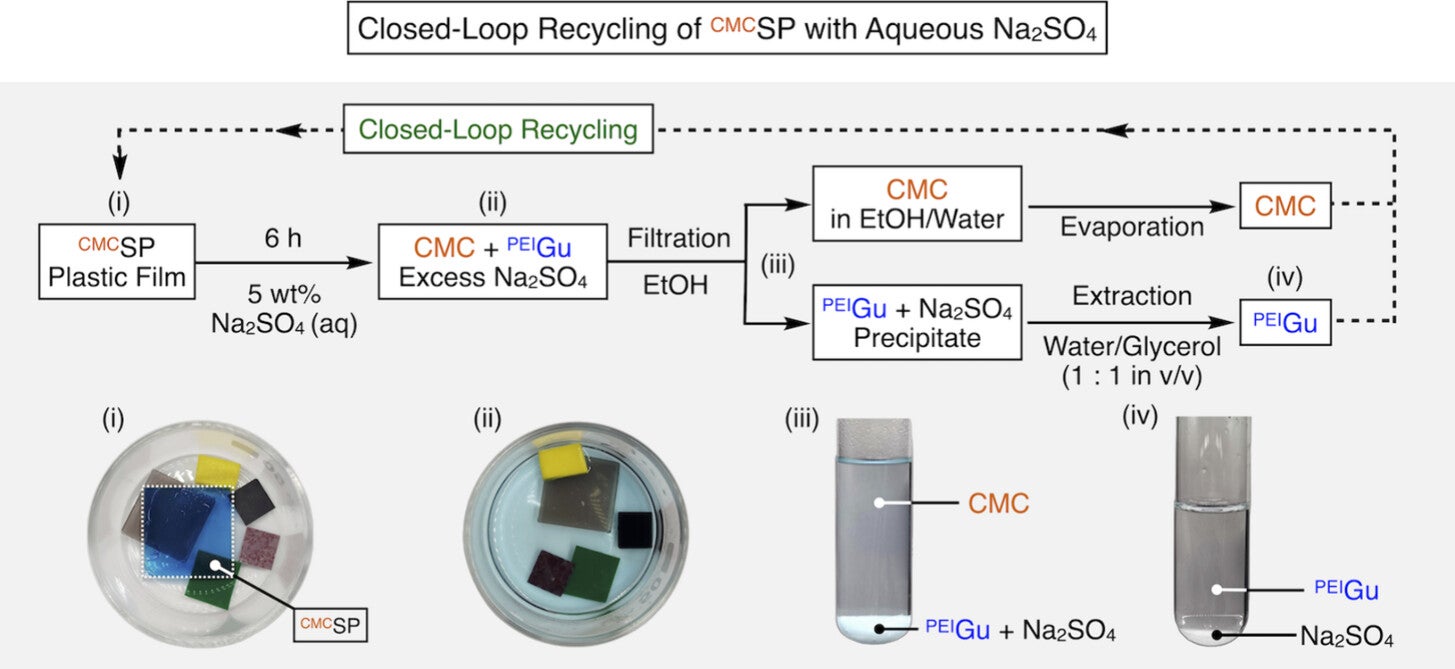

“Despite its strength, our first version of the plastic was brittle. That brittleness limited practical uses, such as packaging films or bags. Even so, the material already offered a major advantage: it could be selectively recycled,” Aida told The Brighter Side of News.

“When mixed with common plastics like polyethylene or polystyrene, only CMCSP dissolved in a mild salt solution. We could then recover both building blocks in high yield and remake the plastic, creating a closed recycling loop,” he continued.

“The material also behaved differently in seawater. While it remained stable in fresh water, the salts in seawater broke its internal bridges, causing it to dissociate into tiny, nonpersistent species. This feature directly addresses the microplastic problem,” he concluded.

To turn the brittle material into something flexible and useful, the team searched for an effective plasticizer. Water and glycerol softened the plastic but weakened it too much. The breakthrough came with choline chloride, an FDA-approved nutrient and food additive.

Adding controlled amounts of choline chloride transformed the material’s behavior. With modest additions, the plastic became tougher and less fragile while staying transparent and recyclable. At higher amounts, it became elastic, stretching more than 100 percent without breaking.

By fine-tuning the choline chloride content, the researchers could dial in properties ranging from glass-like stiffness to rubbery flexibility. At an optimal composition, the plastic reached peak toughness, about three times higher than the unmodified version.

Tests showed that water content alone did not explain this change. Instead, choline chloride altered the internal salt bridges, turning some rigid connections into dynamic links that could break and reform under stress. This allowed the material to absorb energy rather than crack.

The improved plastic could be processed into thin films as little as 0.1 millimeters thick. The team demonstrated a simple bag made from the material that could hold fruits and vegetables. When placed in artificial seawater, the uncoated bag slowly dissolved and disappeared, releasing its contents without leaving fragments behind.

![Folding an uncoated flexible film of CMCSPChCl ([ChCl] = 25 wt %) (i) in half, followed by wet-melding at its edges, affords a flexible and tough plastic bag (ii), which dissolves in artificial seawater and disappears (see Movie S2). CMCSPChCl film (iii) and bag (iv) coated with parylene are tolerant against water and even seawater.](https://www.thebrighterside.news/uploads/2025/12/seawater-4.jpeg)

A thin hydrophobic surface coating offered another option. With this coating, the same bag could safely hold water, even seawater, without dissolving. This showed how surface treatments could control when and where the plastic breaks down.

Cell viability tests suggested low toxicity, supporting potential use in food packaging. The ingredients are inexpensive, widely available, and already approved for human contact, which could ease the path toward real-world applications.

This research points toward plastics designed for their entire life cycle, not just their performance in use. By starting with abundant plant-based materials and using reversible molecular bonds, the new plastic avoids forming microplastics at the end of its life.

Its closed-loop recyclability could reduce waste, while its seawater-triggered dissociation offers a safeguard against marine pollution.

If scaled up, such materials could reshape packaging, reduce environmental cleanup costs, and lower long-term health risks linked to microplastic exposure.

Research findings are available online in the Journal of the American Chemical Society.

Like these kind of feel good stories? Get The Brighter Side of News’ newsletter.

The post Plant-based plastic fully dissolves in seawater eliminating microplastic polution appeared first on The Brighter Side of News.